Slagreus

Reuse of slags from integrated steelmaking

Project abstract

In Europe 2016 steelmaking slags (SMS) amount to 18.4 Mio t/a, of those 10.4 Mio t/a are generated through BOF steelmaking. The majority of slags are used in road construction (46,0 %). Internal recycling for metallurgical use amounts to 15,3 % of the SMS. Unfortunately landfilling already makes up the third biggest share of life cycle destinations. This amount is prone to increase as future EU regulations will cause many SMS not to be permitted for use in road construction. Under the pretext of circular economy, it is desirable to increase internal recycling. That however is limited by the phosphorus content in the slag, due to the deterioration of material properties that would be caused by the phosphorus in steel. SLAGREUS, thus aims to increase internal recycling of primary BOF slag by generation of a high Fe- and low P-slag fraction ready for sintering or direct use in BF and a fraction containing high amounts of Ca and possible free lime for cement production.

This project receives funding from the Research Fund for Coal and Steel under grant agreement No. 847260. The project has started June 1st of 2019 and is set to be concluded on December 1st of 2022.

The research partners involved in the project are:

| VDEh – Betriebsforschungsinstitut GmbH (BFI) |  |

| Voestalpine Stahl GmbH (voestalpine) |  |

| K1-MET GmbH (K1-MET) |  |

| Institut für Baustoff-Forschung e.V. (FEhS) |  |

| Oulun Yliopisto (Uni Oulu) |  |

Objectives

In order to achieve the goal of saving natural resources and reduce landfilling the amount of internally recycled SMS must be increased. It is therefore necessary to develop a new BOF-slag treatment process that allows for the slag to be divided into a fraction of high iron and low phosphorus content and a fraction of high calcium and phosphorus content. The Fe-rich/P-poor fraction will be tested for metallurgical re-use in sinter plants. The Ca-/P-rich fraction will be evaluated as a cement additive, as well as its use in lime fertilizers.

The additional objective of the project is the development of an off-line prediction tool for mass and energy balances of the recycling process, thereby providing information about expected quality and quantities of the slag fractions. The prediction tool will be based on the separation efficiency and specific energy demands of the individual unit operations within the process.

Research approach

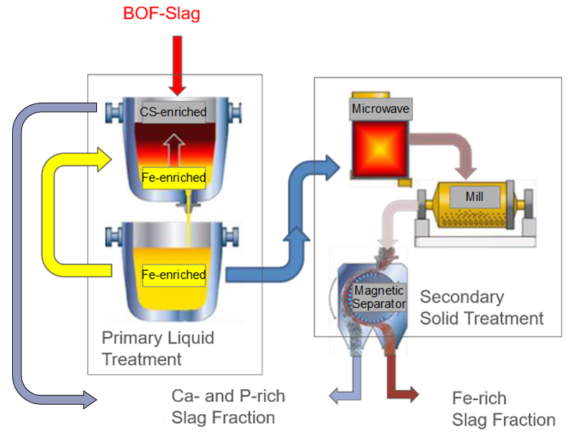

The new process concept is divided into two phases. A primary liquid treatment and secondary solid treatment.

During primary liquid the BOF-slag is slowly cooled to allow for large calcium-silicate crystals to form and segregate to the top of the crucible. The liquid Fe-enriched part is then recirculated into the next slag melt. This facilitates segregation. The obtained calcium-silicate rich phase can already be used as a test material for addition into cement. The iron enriched fraction is slowly cooled to generate large grain sizes, which benefits the secondary solid treatment.

The secondary solid treatment only focusses on the iron enriched fraction obtained from the primary liquid treatment. The first unit operation is the microwave heating of the slag, improving liberation of the individual mineral phases by generating thermally induced tension within the particles. The slag is than ground which the goal to complete phase liberation. The last step of the solid treatment consists of dry magnetic separation, after which the final Fe-rich/P-poor fraction will be separated from the Ca-/P-rich fraction.

During the project the process concept will be implemented and investigated at laboratory and pilot scale. The concept will also be tested on a small industrial scale. During each stage the processing parameters will be evaluated and will contribute to the development of the prediction tool.

First results

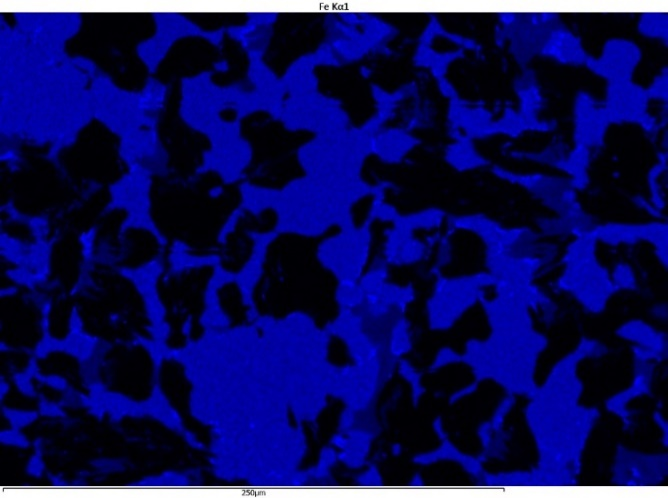

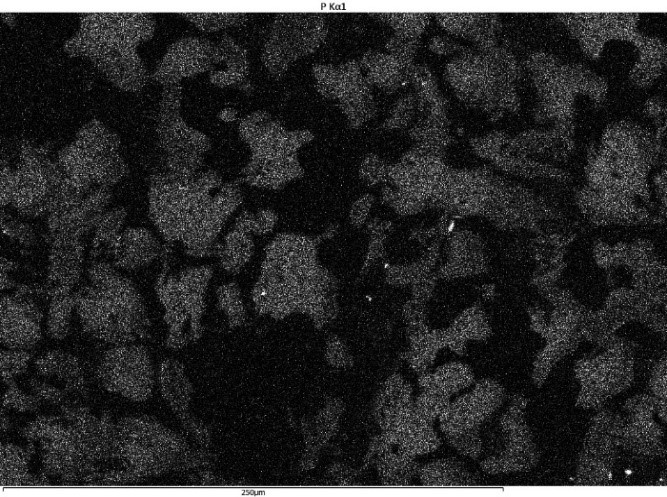

After investigation into grain size distribution and composition via SEM, XRD and XRF of BOF-slag samples, it can be stated that the slow cooling of the slag has the predicted and desired effect of creating large crystal grains with complementary distribution of iron in some phases and phosphorus in other phases. This can be observed in the fluorescence maps depicted in the images below. Iron is marked blue and phosphorous is marked white.

|

|

That indicates, if the mineral phases can be separated, so can iron and phosphorous.